Windsor’s massive Mini Maker Faire brings out the kid in everyone

A stilt walking performer preparing for his appearance at the Mini Maker Faire in Windsor, Ont. Feb. 24, 2018. Photo by Bernard De Vaal.

It’s called the greatest show-and-tell on earth and Windsor launched its own version of the world-renowned Maker Faire for the first time last Saturday.

The original Maker Faire started back in 2006 in San Fransisco. It provides a platform for anyone from scientists to hobbyists to show off their experimental projects and share what they have learned.

“This one brings all the different crafts and makers together all in one space, so there is a huge variety,” said Cathy Mombourquette, program manager of the EPIC Genesis Centre, which hosted the faire. “It exposes everybody, from children to adults, to something that they won’t normally see.”

CO2 laser engraving at the Mini Maker Faire. Photo by Bernard De Vaal.

On show were automated embroidering, CO2 laser engraving and cutting, 3D printing and robots. Lots and lots of robots. The bonus: an interactive environment.

School robotics programs were vying strongly to grab hold of youngsters’ attention for the opportunity to guide them towards mastery of robotics.

These prospective engineers were able to first hone their building skills at Hetherington Public School’s Maker Space stall, where nuts, bolts and brackets were available to style a “mechanimal.”

After mastering the basics, it was off to Villanova Secondary School WiredCats Robotics team’s stall for their first robot. A “bristle bot.”

“To make a bristle bot, you need a motor, a toothbrush and a battery. To complete the circuit, connect the red wire to the positive side of the battery and the blue wire to the negative side of the battery,” said Erica Rossi, a Grade 11 student.

Villanova Secondary School WiredCats Robotic team’s, “build your own bristle bot.” Photo by Bernard De Vaal.

The vibrations of the motor cause the brush head to start moving. It’s the pipe cleaner design that determines how successful the robot will navigate their racecourse. Animal hybrids seemed to work best.

Once the child’s interest in the motorized components had been sparked, the next step: Lego.

From the age of six, students can join the Junior Lego League where they are guided by mentors in the three main components of robotics. Kouthar Waled, a Grade 12 student from Sandwich High School and member of Sabre Bytes team 772 acts as such a mentor.

Junior Lego League robot. Photo by Bernard De Vaal.

“(The Junior Lego League) sparks their interest for mechanical, electrical and programming because there are wires they need to connect motors to,” said Waled. “There are small motors they need to assemble to wheels and to other mechanisms to move. Then there is a program that is block based. Very visual and simple and easy to wrap your mind around.”

The code gets uploaded on the brain of the robot called the brick.

“It sends signals to the motor in the order that they programmed in the code, which makes the motors move,” said Waled.

Things can get tricky when sensors that react to colour or temperature are introduced into the mix.

After a concrete understanding had been developed of compiling these basic building blocks of robotics, they can graduate to competitive building.

A student can join the high school program without any previous knowledge of robotics. FIRST, a non-profit educational organization sets a game challenge for teams in January. They have six weeks to build the robot. Typically, teams will meet three months in advance to learn basic skills and strategize.

Angela Bi, team coordinator of team 772 with Sabre Byte’s competition robot. Photo by Bernard De Vaal.

“The student will gain hands on experience by touching the robot, programming it, wiring it and designing, whatever it is that they’re interested in,” said Angela Bi, team coordinator of team 772.

This year’s game is called “Power-up” where robots must climb and stack cubes.

In the program, students are introduced to the real-world applications of their machines that they put into practice in competitions.

To guide students towards career opportunities in the field, the CAD/CAM and industrial programs at St. Clair College offer mentoring services to help them design and build components for their robots.

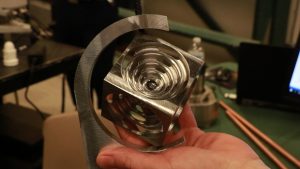

Daniele DeFranceschi, CAD/CAM and industrial coordinator at St.Clair College shows off a industrial design. Photo by Bernard De Vaal.

“We’ll go out to the high schools,” said Daniele DeFranceschi, CAD/CAM and industrial coordinator at St.Clair College. “We’ll say yes, this is a CAD/CAM project, a CNC project, this is a 3D printable. Come over to the college. We’ll help you manufacture those components for your robots.”

To DeFranceschi, the pay-off of involvement in student’s projects is immeasurable when they work with the manufacturing components.

“It’s usually, ‘Wow, it’s so cool. I can’t wait to run one of these myself. I’d love to have one of these in my garage.’”

To Mombourquette, the success of the faire came as a bit of a surprise.

“To be honest I didn’t think it was going to be this popular,” she confessed. “Maybe it’s the weather outside or maybe people really are interested in something like this and we’re just thrilled that it’s been this successful and the intent is to do it every year.”